Lyo Formulations

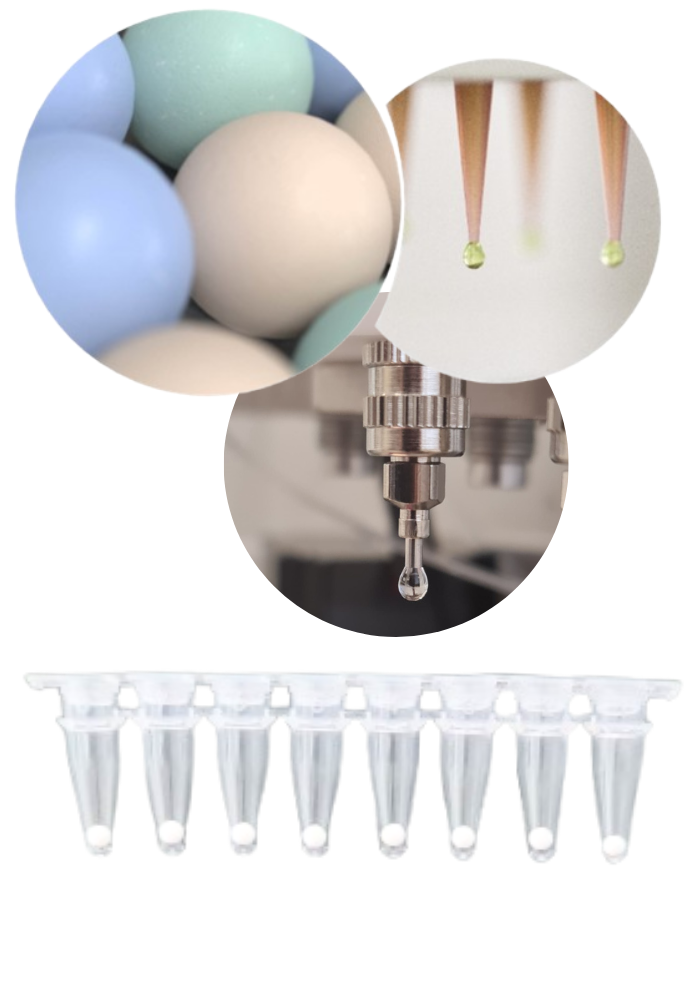

Lyophilization, or freeze-drying, is a widely used technique for stabilizing diagnostics formulations, biologics and heat-sensitive biomolecules. The process involves freezing the formulation, followed by the removal of water through sublimation under reduced pressure, ensuring the preservation of structural integrity and potency. This method enhances the shelf life of the product, improves stability, and allows for easy reconstitution when needed. However, lyophilization requires careful optimization of formulation components, including cryoprotectants and bulking agents, to prevent degradation and maintain efficacy. Despite its advantages, the process can be time-consuming and costly, necessitating precise control over freezing and drying parameters to achieve a high-quality final product. To overcome these challenges Omniprep Private Limited holds thorough understanding of formulation science, advanced process monitoring, and continuous optimization of lyophilization protocols. We use several combinatorial approaches to optimize formulation stability, efficiency, and quality.

Cryoprotectant and Lyoprotectant Selection

The use of excipients such as sucrose, Trehalose, or mannitol helps protect biomolecules from freezing and drying stresses, preserving their stability and functionality.

Optimized Freezing

Techniques

Controlled freezing methods, such as slow freezing, annealing, and controlled ice nucleation, help improve ice crystal formation, reducing heterogeneity and preventing structural collapse.

Primary and Secondary Drying Optimization

Adjusting temp. and pressure during Pr. drying (sublimation) and Sec. drying (desorption) ensures effective moisture removal while preventing degradation or denaturation of sensitive compounds.

Use of Stabilizers

& Buffers

Incorporating stabilizers and pH buffers prevents pH shifts, protein aggregation, or chemical instability during lyophilization and storage.

Lyophilization Cycle

Optimization

Using computational modeling and process analytical technology (PAT) allows precise control of lyophilization cycles, improving efficiency, reducing cycle times, and ensuring reproducibility.